|

We can recommend a wide range of equipment and production machinery made mainly of FRP with superior levels of corrosion resistance, durability, heat resistance and weather resistance.

|

|

| 1. |

Can be used for a wide range of applications.

Standardized with a wide range of variations from 25A small diameter through to 200A large diameter to provide extremely economic and swift processing without individual designs. |

| 2. |

Superior levels of corrosion resistance and durability

The areas that come into direct contact with chemical solutions have superior levels of corrosion resistance, so there is no fear of corrosion-related trouble. |

| 3. |

Superior levels of heat resistance and weather resistance

Superior levels of heat resistance for chemical solutions at temperatures up to 100 degrees Celsius guaranteed. They can also be used for long periods of time without the cracks and crevices that appear on PVC materials owing to ultraviolet rays and oxygen. |

| 4. |

Light and tough

Easy to handle with a specific gravity that is 1/5th lighter than iron. The pumps have a similar strength to metal. They will stand up to hard operations over long periods of time. |

| 5. |

Able to withstand electrolytic corrosion

High levels of electrical insulation, so there is no need to worry over electrolytic corrosion or internal liquid contamination caused by rust and metallic ion elution. |

| 6. |

Standardized

All items in the lineup are standardized, to replacement parts can be supplied immediately. |

| 7. |

Wide-ranging experience

We have built up a wide range of experience and results over the course of many years, and will provide consultations on all types of issues related to corrosion. |

|

|

| |

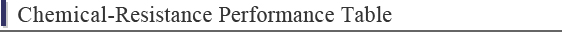

% |

C10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

|

| Mineral Acid |

Sulfuric Acid |

|

25 |

|

|

|

|

|

|

|

|

|

|

|

Sulfuric Acid |

|

70 |

|

|

|

|

|

|

|

|

|

|

|

Nitric Acid |

|

5 |

|

|

|

|

|

|

|

|

|

|

|

Sulfuric Acid/ Iron Sulfate(II) |

|

10/Saturation |

|

|

|

|

|

|

|

|

|

|

|

Sulfuric acid/ Nitric Acid (50/50) |

|

30 |

|

|

|

|

|

|

|

|

|

|

|

Sulfur/Phosphoric Acid |

|

10/20 |

|

|

|

|

|

|

|

|

|

|

|

Sulfurous Acid |

|

10 |

|

|

|

|

|

|

|

|

|

|

|

Phosphorous Acid |

|

70 |

|

|

|

|

|

|

|

|

|

|

|

Hydrochloric Acid |

|

20 |

|

|

|

|

|

|

|

|

|

|

|

Hydrochloric Acid |

|

37 |

|

|

|

|

|

|

|

|

|

|

|

Hydrochloric Acid + Chlorine |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Perchloric Acid |

|

10 |

|

|

|

|

|

|

|

|

|

|

|

Chromic Acid |

|

10 |

|

|

|

|

|

|

|

|

|

|

|

Hydrobromic Acid |

|

25 |

|

|

|

|

|

|

|

|

|

|

|

Silicon Tetrafluoride |

£ |

35 |

|

|

|

|

|

|

|

|

|

|

|

Hydrofluoric Acid |

£ |

5 |

|

|

|

|

|

|

|

|

|

|

|

Phosphoric Acid |

£ |

Total Concentration |

|

|

|

|

|

|

|

|

|

|

| Inorganic Hydroxide |

Ammonium Hydroxide |

|

20 |

|

|

|

|

|

|

|

|

|

|

|

Sodium Hydroxide |

|

25 |

|

|

|

|

|

|

|

|

|

|

|

Sodium Hydroxide |

|

50 |

|

|

|

|

|

|

|

|

|

|

| Inorganic Salt |

Ammonium Hydrogen Sulfite (cooking liquor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Ammonium Hydrogen Sulfite (black liquor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Calcium Hydrogen Sulfite |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Sodium Sulfite |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Zinc Chloride |

|

70 |

|

|

|

|

|

|

|

|

|

|

|

Aluminum Chloride |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Ammonium Chloride |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Calcium Chloride |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Iron Chloride (I) (III) |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Sodium Chloride, PH10.5 (Saturation c12) |

|

Saturation |

|

|

|

|

|

|

|

|

|

|

|

Sodium Chromate |

|

50 |

|

|

|

|

|

|

|

|

|

|

|

Sodium Silicate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Aluminum Nitrate |

|

100 |

|

|

|

|

|

|

|

|

|

|

|

Ammonium Nitrate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Iron Nitrate (II) |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Sodium Hypochlorite |

¢ |

Up until a stable temperature |

|

|

|

|

|

|

|

|

|

|

|

Sodium Dichromate |

|

100 |

|

|

|

|

|

|

|

|

|

|

|

Ammonium Carbonate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Potassium Carbonate |

£ |

25 |

|

|

|

|

|

|

|

|

|

|

|

Sodium Carbonate |

£ |

10 |

|

|

|

|

|

|

|

|

|

|

|

Sodium Thiocyanate |

|

57 |

|

|

|

|

|

|

|

|

|

|

|

Ammonium Thiosulphate |

|

60 |

|

|

|

|

|

|

|

|

|

|

|

Sodium Thiosufate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Aluminium Fluoride |

£ |

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Ammonium Fluoride |

£ |

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Sodium Silicofluoride |

£ |

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Barium Sulfide |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Zinc Sulfate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Aluminum Sulfate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Potassium Sulfate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Chromium Sulfate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Iron Sulfate (II) |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Nickel Sulfate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Barium Sulfate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Sodium Phosphate |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

| Plating Solution |

Zinc Solution |

|

|

|

|

|

|

|

|

|

|

|

|

|

Gold Plating Solution |

|

|

|

|

|

|

|

|

|

|

|

|

|

Silver Plating Solution |

|

|

|

|

|

|

|

|

|

|

|

|

|

Chrome Plating Solution |

|

|

|

|

|

|

|

|

|

|

|

|

|

Zinc Cyanide Plating Solution |

|

|

|

|

|

|

|

|

|

|

|

|

| Paper/Pulp/Fiber-Related Chemicals |

Chlorine Water |

|

Saturation |

|

|

|

|

|

|

|

|

|

|

|

Ozone |

¢ |

0.5 |

|

|

|

|

|

|

|

|

|

|

|

Perchloric Acid |

|

30 |

|

|

|

|

|

|

|

|

|

|

|

Chlorine Dioxide |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

|

Hydrogen Sulfide |

|

Total Concentration |

|

|

|

|

|

|

|

|

|

|

| Organic Acid |

Acetic Acid |

|

75 |

|

|

|

|

|

|

|

|

|

|

|

Monochloroacetic Acid |

|

50 |

|

|

|

|

|

|

|

|

|

|

1. Indicates the permissible temperature range when standard polymers are being used. 1. Indicates the permissible temperature range when standard polymers are being used.

2. Indicates the additional permissible temperature range when special polymers are being used. 2. Indicates the additional permissible temperature range when special polymers are being used.

3. Take particular care when gas-liquid interfaces occur with (2).

Organic fibers or carbon fibers must be used on the inner surface with (3).

|

|

|

|

|

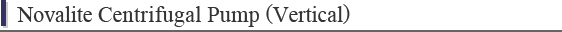

| Model No. |

Discharge Pipe |

Pumping Volume |

60Hz |

50Hz |

Number of Motor Poles |

| mmφ |

l/min |

Pumping Height (m) |

Shaft Power (kw) |

Pumping Height (m) |

Shaft Power (kw) |

| KVPL (M) 0251 |

25 |

45 |

14 |

1.0 |

9 |

0.7 |

4 |

| KVPL (M) 0252 |

19 |

1.4 |

13 |

1.0 |

4 |

| KVPL (M) 0401 |

40 |

130 |

14 |

1.3 |

9 |

1.0 |

4 |

| KVPL (M) 0402 |

21 |

2.3 |

14 |

1.6 |

4 |

| KVPL (M) 0403 |

27 |

3.0 |

18 |

2.2 |

4 |

| KVPL (M) 0501 |

50 |

220 |

14 |

2.0 |

9 |

1.3 |

4 |

| KVPL (M) 0502 |

21 |

2.9 |

13 |

2.0 |

4 |

| KVPL (M) 0503 |

27 |

4.0 |

18 |

2.8 |

4 |

| KVPL (M) 0651 |

65 |

350 |

14 |

2.5 |

9 |

1.7 |

4 |

| KVPL (M) 0652 |

21 |

3.6 |

14 |

2.6 |

4 |

| KVPL (M) 0801 |

80 |

560 |

14 |

3.4 |

9 |

2.3 |

4 |

| KVPL (M) 0802 |

21 |

5.0 |

14 |

3.5 |

4 |

| KVPL (M) 0803 |

27 |

6.4 |

18 |

4.4 |

4 |

| KVPL (M) 1001 |

100 |

1,000 |

14 |

5.4 |

9 |

3.6 |

4 |

| KVPL (M) 1002 |

21 |

8.0 |

14 |

5.5 |

4 |

| KVPL (M) 1003 |

27 |

10.2 |

18 |

6.9 |

4 |

| KVPL (M) 1251 |

125 |

1,600 |

14 |

7.8 |

9 |

5.2 |

4 |

| KVPL (M) 1252 |

21 |

11.5 |

14 |

7.8 |

4 |

| KVPL (M) 1501 |

150 |

2,500 |

14 |

11.1 |

9 |

7.5 |

4 |

| KVPL (M) 1502 |

150 |

2,500 |

21 |

17.0 |

14 |

11.6 |

4 |

| KVPL (M) 2001 |

200 |

4,000 |

16 |

20.2 |

10 |

13.1 |

4 |

* Shaft power figures when used with pure water (specific gravity of 1.0.)

We are also able to manufacture models for use with specifications not listed above.

* Reverse operations may result in damage.

|

|

|

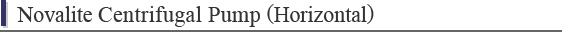

| 1. |

A high-performance auto-suction centrifugal pump made of FRP. |

| 2. |

There are two types of shaft seal available, a gland packing model and a mechanical seal mode, and the shaft that comes into contact with the liquid has been appropriately selected from FRP, titanium and hastelloy, etc., to withstand corrosion in order to provide superior levels of reliability and durability. |

| 3. |

The pump is an auto-suction model, and it can begin to pump water after being primed just once at the beginning, so it is very easy to handle. |

| 4. |

The auto-suction performance has been standardized at -5m, and the pumping height between 10m and 25m. |

|

Uses for the Novalite Centrifugal Pump Uses for the Novalite Centrifugal Pump

Can be used with strong acids, oxidizing acids, strong alkalis and other solutions used by the chemical industry, and for processing all types of corrosive waste water.

Novalite Centrifugal Pump Models Novalite Centrifugal Pump Models

Outlet Diameter: 25 to 130mm ¦Õ

Discharge Volume: 20 to 2000l/min

Total Pumping Height: 5 to 25m

|

|

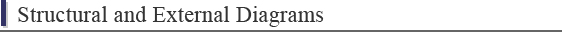

Novalite Auto-Suction Pump Standard Part Material Chart Novalite Auto-Suction Pump Standard Part Material Chart

| Part No. |

Part Name |

Material |

1 unit/set |

| Quantity |

| 1 |

Casing |

FRP |

1 |

| 2 |

Casing Cover |

FRP |

1 |

| 3 |

Suction Pipe |

FRP |

1 |

| 4 |

Impeller |

FRP |

1 |

| 5 |

Spacer Flange |

FRP |

1 |

| 6 |

O-ring |

FPM |

1 |

| 7 |

Flap Valve |

EPT |

1 |

| 8 |

Stud Bolt |

SUS304 |

8 |

| 9 |

Drain Inlet Cap |

FRP |

1 |

| 10 |

Packing |

EPT |

1 |

| 11 |

Stud Bolt |

SUS304 |

12s |

| 12 |

Bearing Housing |

FC200 |

1 |

| 13 |

Shaft |

SUS304 |

1 |

| 14 |

Sleeve |

Teflon,HC,FRP,Ti |

1 |

| 15 |

Collar |

SUS316 |

1 |

| 16 |

Ball Bearing |

SUJ |

2 |

| 17 |

Bearing Inserter |

FC200 |

1 |

| 18 |

Bearing Inserter |

FC200 |

1 |

| 19 |

Bearing Nut |

SS400 |

1 |

| 20 |

Bearing Washer |

SS400 |

1 |

| 21 |

Coupling |

FC200 |

1s |

| 22 |

Key |

S45C |

1 |

| 23 |

Grease Nipple |

BS |

2 |

| 24 |

Oil Seal |

NBR |

1 |

| 25 |

Oil Seal |

NBR |

1 |

| 26 |

Draining Ring |

CR |

1 |

| 27 |

O-ring |

FPM |

1 |

| 28 |

Stuffing Box1 |

FRP |

1 |

| 29 |

Stuffing Box2 |

FRP |

1 |

| 30 |

Stuffing Box3 |

FRP |

1 |

| 31 |

Hexagonal Bolt with Hexagonal Hole |

SUS304 |

4 |

| 32 |

Hexagonal Bolt |

SUS304 |

4s |

| 33 |

O-ring |

FPM |

1 |

| 34 |

O-ring |

FPM |

1 |

| 35 |

Oil Seal |

NBR |

1 |

| 36 |

Securing Ring |

|

1 |

| 37 |

O-ring |

FPM |

1 |

| 38 |

Seal Ring |

Carbon |

1 |

| 39 |

O-ring |

FPM |

1 |

| 40 |

Sealing Case |

|

1 |

| 41 |

Set Collar |

|

1 |

| 42 |

Spring |

|

1 |

| 43 |

Set Screw |

|

2 |

| 44 |

Common Base |

SS |

1 |

* Reverse operations may result in damage.

Novalite Centrifugal Pump Performance (50Hz) Novalite Centrifugal Pump Performance (50Hz)

Novalite Centrifugal Pump Performance (60Hz) Novalite Centrifugal Pump Performance (60Hz)

Note:

1. The above performance chart is based on when used with pure water (specific gravity of 1.0.)

2. Listing Example: 25-3/1.5 indicates the [diameter of the discharge outlet - pumping height / motor output (kw)].

|

|