|

|

|

|

| Home > Machine Outlines > Pulverizing Mills |

|

|

|

The Super Jet Mill is an ultra-fine grinding mill that grinds materials with just compression forces, as opposed to a drive unit. Air is jet-fed with multiple grinding nozzles located on the top of the circumference, which grinds the particles by impact and friction when they collide.

Disturbances in the rotational flow inside the mill were analyzed, and rectifying the flow enabled us to develop a grinding mill that produces sharp particle distribution with very little coarse particle getting mixed in.

|

|

| 1. |

Extremely sharp particle distribution

The effect of the second-stage distribution applied by the unique inner configuration enables only particles with the same diameter to be efficiently obtained.

This is perfectly suited to grinding materials that demand not only equal particle diameters, but also sharp particle distribution.

|

| 2. |

Wear resistant and contamination resistant specifications

The use of ceramic-sintered materials on the areas that come into direct contact with the particle, which are a cause of wearing, has produced superior levels of durability. The metal surfaces in the grinding zone are also not exposed, which prevents contamination.

In addition to SiAION (standard), AI203, Zr-02 and Sic are also available for the ceramic-sintered materials, so it is possible to select the material that is best suited for the particles to be ground.

|

| 3. |

Easy dismantling and cleaning

The grinding mill does not contain a drive unit, so dismantling and cleaning it is extremely easy. Also, all models can be washed with water to prevent cross-contamination between production lots.

|

| 4. |

No heat generation

The grinding principle relies only on compressed air, so no heat is generated. This makes it perfect for grinding food, polymers, pharmaceuticals and other particles that are adversely affected by heat.

|

| 5. |

Built-in cyclone

Built-in cyclone

The specifications include a built-in cyclone in which the grinding zone and collection zone are connected together to ensure that particles with a tendency to stick together can be efficiently collected.

There is consequently no need to install a separate cyclone on the outside of the grinding mill, which greatly simplifies the system.

|

|

|

| Model |

Air Volume [m3/min] |

Processing Capacity [kg/hr] |

Dimensions D x H [mm] |

Weight [kg] |

Compressor Power [kW] |

| SJ-100 |

0.2пҪһ0.3 |

0.05пҪһ0.3 |

φ160×140 |

5 |

2.2 |

| SJ-100GMP |

0.2пҪһ0.3 |

0.05пҪһ0.3 |

L720×W370×H600 |

50пјҲweight of systemпјү |

2.2 |

| SJ-500 |

0.8пҪһ1.2 |

0.5пҪһ10 |

φ320×180 |

27 |

7.5пҪһ11 |

| SJ-1500 |

2.0пҪһ3.0 |

2.0пҪһ30 |

φ400×180 |

45 |

15пҪһ22 |

| SJ-500GMP |

2.0пҪһ3.0 |

2.0пҪһ30 |

L900×W950×H1550 |

250пјҲweight of systemпјү |

15пҪһ22 |

| SJ-2500 |

3.0пҪһ4.5 |

3.0пҪһ50 |

φ500×180 |

65 |

22пҪһ37 |

| SJ-5000 |

6.0пҪһ9.0 |

5.0пҪһ150 |

φ600×350 |

120 |

45пҪһ75 |

| SJ-10K |

12.0пҪһ18.0 |

10пҪһ300 |

φ700×350 |

180 |

75пҪһ110 |

|

| |

|

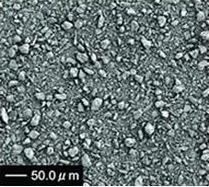

Grinding glass particles Grinding glass particles

|

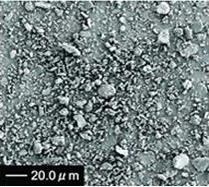

Grinding pharmaceuticals Grinding pharmaceuticals

|

|

|

|

| |

|

|

Turbo classifier |

Grinding with a classifier.

The grinding mill is connected directly to the classifier to enable high levels of grinding and classification efficiency.

Will effectively grind all types of materials, from a few mm through to sub-micron orders.

|

|

| |

|

|

|

|

| |

|

|

|

|

|