|

We will provide the fin dry powder by the most up - dated fourfluid nozzle!

| |

Micro mist Spray dryer |

Spray dryer |

| Four-fluid nozzle |

Two-fluid nozzle |

Pressure nozzle |

Rotary atomizer |

| Atomization evenly |

Atomic |

Atomic |

coarse grain |

coarse grain |

| 5¡Á15μm |

5¡Á30μm |

0¡Á150μm |

10¡Á100μm |

| Atomization evenly |

Evenly |

unevenly |

a little unevenly |

Evenly |

| Atomization method |

Compressed gas |

Compressed gas |

Pressure pump |

Motors |

| Atomization energy |

Big |

Big |

Small |

Small |

| Processing liquid measure |

Large |

Small |

Medium |

Large |

| Droplet diameter control |

Fine grain area ¡ý |

¢¤ |

¢¤ |

¡ý |

| The measure against a viscosity change |

Air pressure |

Air pressure |

Liquid pressure |

Revolutions rpm |

| Liquid high viscosity |

¡ý |

¡û |

× |

¡û |

| Maintainability |

¡ý |

¡ý |

¡û |

¢¤ |

| Angle of spray |

180¡ë |

Under 30¡ë |

Under 60¡ë |

180¡ë |

| Spraying form |

Hollow cone |

Full cone atomic |

Hollow cone atomic |

Hollow cone |

Comparison in atomization device

| |

Few microns |

Scores of microns |

| Surface area |

If the case of 5 ¦Ì£í is set to 1 |

50 ¦Ìm It is Case of 100 |

| Volume |

If the case of 5 ¦Ì£í is set to 1 |

50¦Ìm It is Case of 1000 |

| Surface area to volume |

1 is received in the case of 5 ¦Ìm. |

50¦Ìm It is Case of 1/10 |

| The solid to 1 ml |

In the case of 5 ¦Ì m, it is about 15,280 million |

In the case of 50 ¦Ìm, it is about 15,280,000 |

| Drying time |

Instant |

Several seconds |

| drying temperature |

It can do low

The drying temperature below the boiling point is possible |

At the temperature below the boiling point, it is difficult |

| undried |

Never |

Exhaust temperature and retention time need consideration |

| Slurry initial particles |

Need better to be 1 to 2¦Ìm |

Below 10¦Ìm |

| handling |

Never |

good |

| Collection method |

Cyclone and bag filter or

Only bag filter |

Cyclone

Bag filter for a dust collector |

| Mobility |

wrong |

good |

| Solubility |

good |

wrong |

| Tap density |

good |

wrong |

| Reactivity |

good |

wrong |

| Novelty of product |

Present |

None |

|

| |

|

|

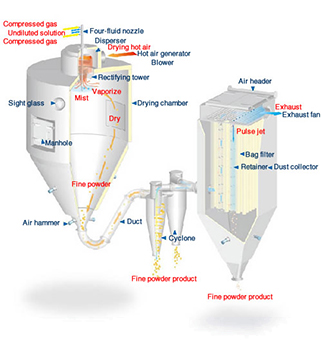

MDL-050C MDL-050C

Simple type that collects by Cyclone and bag filter at the bottom

|

|

MDL-050M MDL-050M

Continuous collecting type by the bag filter unit

|

|

MDL-050SB MDL-050SB

GMP available type

|

|

MDP-050 MDP-050

Water evaporate capacity 50kg/hr

Drying chamber size¡¡ diameter ¦Õ2.5m

Height 4.5m

|

|

MDP-200 MDP-200

Water evaporate capacity 200kg/hr

Drying chamber size¡¡ diameter ¦Õ3.8m

Height 5.5m

|

|

|

MDP series is a visitor's demand. It unites with (a process example and an installation space), and manufactures

The feature of the equipment which used [four-fluid nozzle] as an atomization device,

¡üThe dust-size particle end of several microns it was not able to build with old equipment is producible in large quantities.

¡üShort residence time inside the drying chamber , its structure can be smaller

¡üWhen searching for few microns particles object, neither pulverization nor classification operation is needed, but a product is obtained.

¡üThe fluid material which is hard to dry, and since there is thermosensitivity again, what has required low-temperature drying can be dried by droplet being several microns.

¡üSince it corresponds to scale-up, a plan can be smoothly shifted from research to production.

|

|

|

|

Ceramics Ceramics |

Cosmetics Cosmetics |

Barium titanate Barium titanate |

Pigment Pigment |

Battery material Battery material |

Silica Silica |

Titanium oxide Titanium oxide |

Amino acid Amino acid |

Ferrite Ferrite |

Phenol resin Phenol resin |

Zirconia Zirconia |

Epoxy resin Epoxy resin |

|

|

|

|

|

|

|

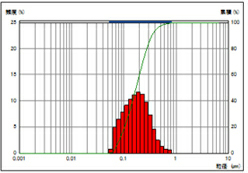

It depends Other a dry

Particle size distribution after wet-grinding |

Fujisaki electric co, Ltd

It depends micro mist dryer

Particle size distribution after spray drying |

|

|

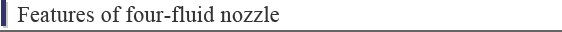

| A principle builds mist with the shock wave which occurs with the collision focus at the tip of nozzle edge for the fluid which came out from two gas ways and two liquid ways to make the collision focus gathering in one point form. |

|

An atomizing unit accounts for an important role in spray drying.

Generally, a rotary atomizer (rotating disk) pressurization nozzle and the binary tow-fluid nozzle using compression gas are used. In these, a binary two-fluid nozzle can make the diameter of a particle small most.

And the principle of this binary two-fluid nozzle was further pursued, and it succeeded in development of the [four- fluid nozzle] which can be sprayed in large quantities in the domain of a [single micron].

It a features

¡üExtensive spraying of droplet of a [single micron] was attained

¡üDroplet diameter to control is possible

¡üDifferent kind of liquid the tip of nozzle mixing spray is possible

¡üSharp granule distribution

¡üOutside mixing nozzle of automatic flushing device ,long time operation without adhesion clogging

¡üCorrespond to scale-up by changing length of edge

|

|

|

|