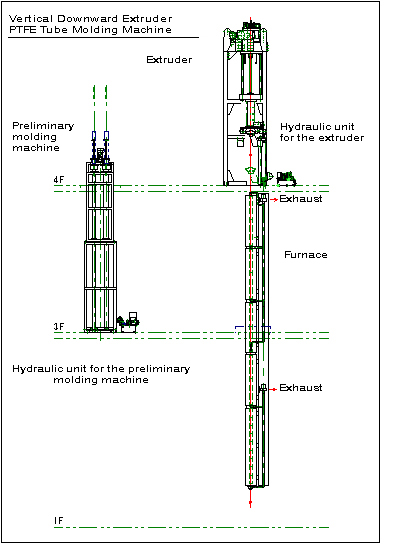

Vertical Tube Molding Machine

Vertical Tube Molding Machine

Can be used in a wide range of fields that make the best use of the fluorine plastic in PTFE polymer tubes, such as in automobiles, chemical and pharmaceutical pipes and the medical field.

Molding Flow

The tubes are molded (room-temperature molding) with the extruder and then passed through the furnace to produce dry-fired products.

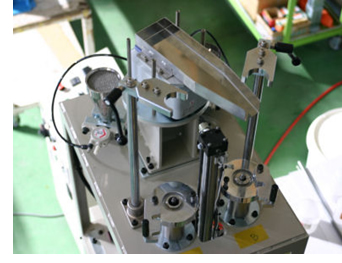

Paste Extruder-related Equipment

We have a full line-up of unique related equipment for paste extrusion molding in addition to regular extruders.

Blender

A machine for mixing PTFE polymer powder and naphtha, which is used as an auxiliary ingredient.

Preliminary Molding Machine

(Pre-former)

Extrusion is carried out in batches, as was mentioned previously, and it is therefore necessary for the PTFE polymer powder to be preliminarily hardened in a cylindrical shape in order to fill the extruder with polymer.

This is the item of equipment that enables that.

Dryer / Furnace Dryer / Furnace

The molded products that have been extrusion molded at room temperature are still soft at this stage. They are dried after extrusion and then the polymer is heated to a gelation temperature. The temperature is set in stages from 100 degrees Celsius to a maximum of about 500 degrees Celsius.

This is carried out in the furnace, which requires stability in the temperature settings.

Dryer Haul-off Machine

Dryer haul-off machines, which are mostly incorporated into cable covering devices, are a form of furnace mainly designed to steam-dry naphtha.

Machines for Special Applications

Machines for Special Applications

Rounded string-shaped polymers are formed in the PTFE polymer paste extruder, and these are then rolled out into a sheet/film-shape with calendering rolls to produce a porous film.

There are also cases in which the calendering rolls are combined with drawing equipment for stretching the film in both horizontal and vertical directions and other equipment.

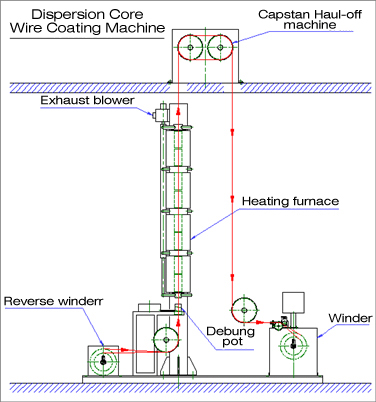

Dispersion Molding

Another method of molding PTFE polymers is to dissolve fine polymer powder in water and then pass wire or glass cloth through the solution this produces (dispersion) to create an extremely thin polymer film, which is heated to solidify it.

Glass Cloth Impregnation Furnace

An item of equipment that manufactures products using PTFE polymers with high levels of slipperiness, heat and weather resistance, and high frequency property, such as tent material, conveyor belts and printed circuits, etc., that consist of glass cloth that has been coated.

Dispersion Core Wire Coating Machine Dispersion Core Wire Coating Machine

This is a molding method that utilizes the dispersion method to coat wire with an extremely thin film of PTFE polymers (from a few microns through to about 20 microns,) which is difficult to perform with paste extruders.

|