|

|

|

|

| Home > Machine Outlines > Single Screw Extruders > Processing Examples |

Back to products details¡¡¡¡ Back to products details¡¡¡¡ See other products See other products |

¢£Features of the Ikegai T-shaped Coat-hanger Die:

| 1¡Ë |

Stream surface shapes with computer analyses

The shape of evenly-poured polymer stream surfaces are calculated in detail by polymer and by grade, and the results are then corrected and redesigned in accordance with accumulated evidence. |

| 2¡Ë |

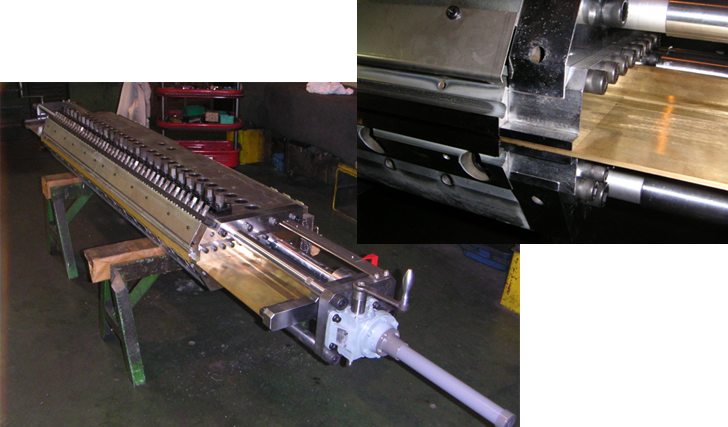

In-house high-precision processing

Processing and automatic polishing through centralized technology with our machine tools. |

| 3¡Ë |

Finishing processes by highly-skilled technicians

Human techniques put to use in stream surface polishing and final finishing. |

| 4¡Ë |

Production management

Concentrated management of high quality, short delivery deadlines and low costs. |

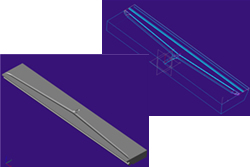

¢£High-precision Processing with Flow Analysis and CAD/CAM

Direct transferred to the special coat-hanger die processing machine. Direct transferred to the special coat-hanger die processing machine. |

Flow Analysis Example Flow Analysis Example |

3-Dimensional T-Die Diagram 3-Dimensional T-Die Diagram |

|

|

|

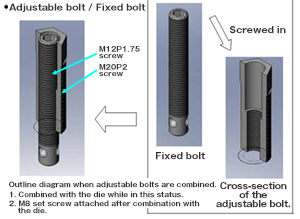

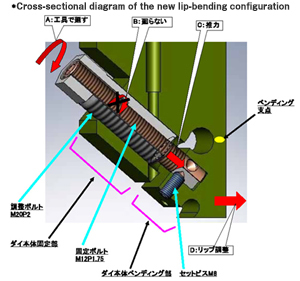

Description of Operation Screws Description of Operation Screws |

¡¡ ¡¡ |

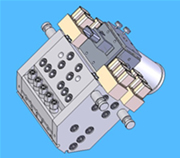

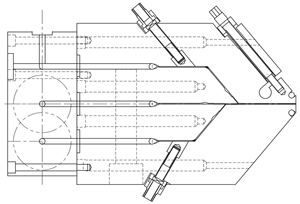

¢£Special Ikegai Coat-hanger Die Processing Machine

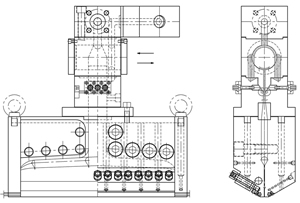

¢£Ikegai T-die with Width Zeckle

TZ1300 Die

TZ1300 Die TZ1300 Die

* The entire manifold has been made moveable to create a configuration that prevents build-ups during lip width modifications.

T-die lip width adjustment method T-die lip width adjustment method

Outer deckle Outer deckle

Inner deckle Inner deckle

Full-width manifold deckle Full-width manifold deckle |

|

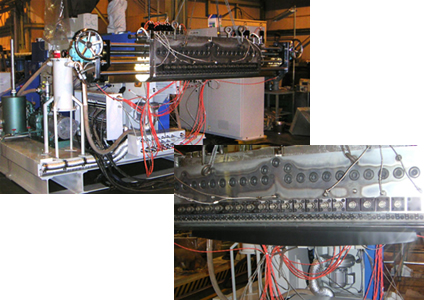

¢£Actual Example of a Full-width Deckle Die Extruder

|

Ikegai GT110 extruder Ikegai GT110 extruder

TZ1450/750 TZ1450/750

Full-width deckle die Full-width deckle die

PVA extruder prototype PVA extruder prototype |

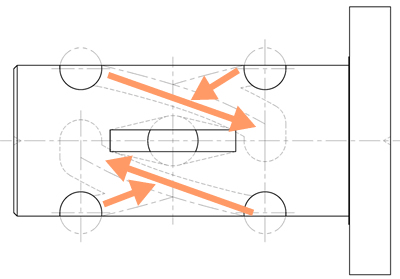

¢£Laminate Feed Block and T-Die

Utilizes a polymer layer-flow method. Utilizes a polymer layer-flow method.

Made possible with a classifying valve and cartridge. Made possible with a classifying valve and cartridge.

Can be used for tri-fold 3-laminate, 4-laminate and 5-laminate film. Can be used for tri-fold 3-laminate, 4-laminate and 5-laminate film.

Classifying valve (channel-change parts). Classifying valve (channel-change parts).

Cartridge-type. Cartridge-type. |

|

¢£Multi-manifold Laminating Die

|

Coat-hanger T-die. Coat-hanger T-die.

Laminating overlay type. Laminating overlay type.

All layers the same thickness. All layers the same thickness.

Each layer of polymer has temperature-controlled viscosity similarities. Each layer of polymer has temperature-controlled viscosity similarities. |

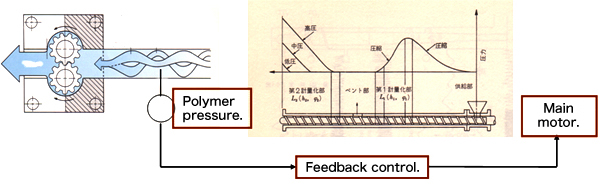

¢£Gear Pump Features

Stable Extruder Volume. Stable Extruder Volume.

Extruder Volume can be increased. Extruder Volume can be increased.

Minimizes heat emissions. Minimizes heat emissions.

* The extrusion pressure from the die is managed by the gear pump.

* Possible to minimize the screw pressure.

|

|

| |

|

| |

|

|

|

|

|